In industrial settings, the need for effective production isolation is paramount. One solution that has gained popularity is the use of aluminum honeycomb blind plates. These plates offer numerous advantages in ensuring the complete separation of production mediums. In this article, we will delve into the various benefits of aluminum honeycomb blind plates and their role in enhancing production isolation.

I. Understanding Aluminum Honeycomb Blind Plates

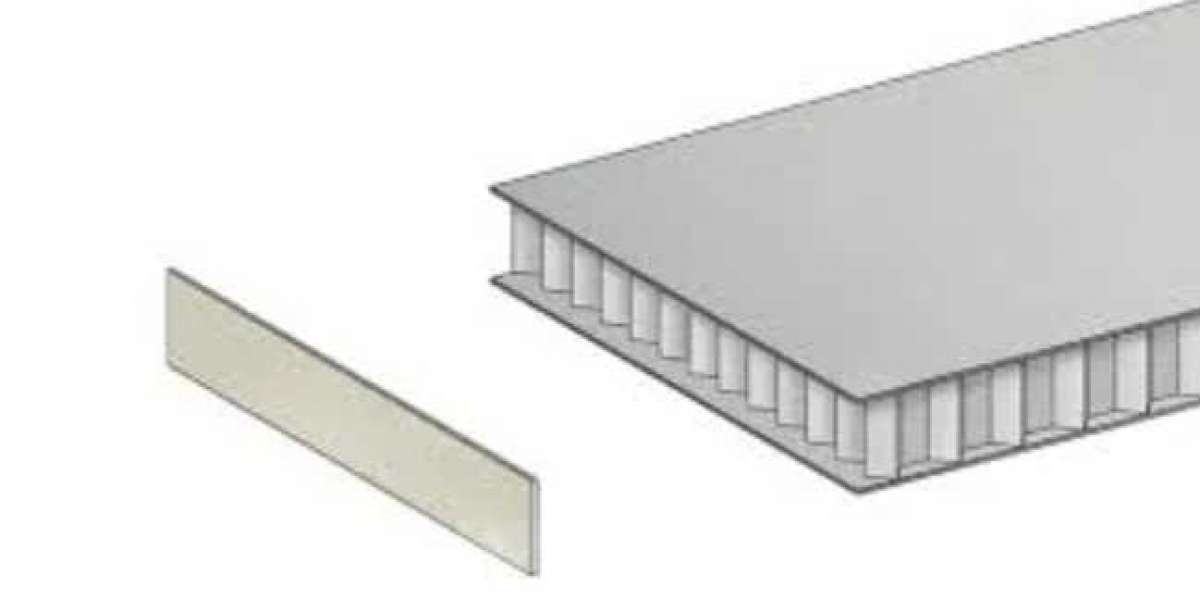

Aluminum honeycomb blind plates are specially designed panels used to isolate production mediums. They are composed of a central core made of aluminum honeycomb structure, sandwiched between two layers of aluminum sheets. This unique composition provides the plates with exceptional strength and durability.

II. Advantages of Aluminum Honeycomb Blind Plates in Production Isolation

A. Complete Medium Separation

One of the primary advantages of aluminum honeycomb blind plates is their ability to ensure complete medium separation. By installing these plates, businesses can prevent cross-contamination between different production processes. This is particularly crucial in industries such as pharmaceuticals, food processing, and chemical manufacturing, where maintaining product purity is of utmost importance.

B. Enhanced Safety

Aluminum honeycomb blind plates offer enhanced safety by providing a barrier against hazardous substances. In industries dealing with toxic chemicals or volatile materials, these plates act as a protective shield, minimizing the risk of accidents and exposure to harmful substances. Additionally, they can help contain fires and prevent the spread of flames in case of emergencies.

C. Improved Efficiency

Efficiency is a key factor in any industrial operation. Aluminum honeycomb blind plates contribute to improved efficiency by optimizing production processes. By isolating different production mediums, businesses can prevent interference and ensure each process operates at its optimal conditions. This leads to increased productivity, reduced downtime, and lower maintenance costs.

D. Noise and Vibration Control

Noise and vibrations are common in industrial environments and can have detrimental effects on both workers and equipment. Aluminum honeycomb blind plates help control noise levels by acting as sound barriers, creating a quieter work environment. Additionally, they absorb vibrations, reducing the risk of equipment damage and extending the lifespan of machinery.

III. Applications of Aluminum Honeycomb Blind Plates

Aluminum honeycomb blind plates find applications in various industries where production isolation is critical. Some notable examples include:

A. Pharmaceutical Industry

In pharmaceutical manufacturing, maintaining sterility is crucial. Aluminum honeycomb blind plates help ensure the isolation of different production areas, preventing cross-contamination and maintaining the purity of drugs. They are also used to isolate hazardous chemicals, protecting workers and the environment.

B. Food Processing Industry

The food processing industry requires strict adherence to hygiene standards. Aluminum honeycomb blind plates are used to separate different production areas, preventing cross-contamination and maintaining the integrity of food products. They are particularly useful in facilities handling allergens or sensitive ingredients.

C. Chemical and Petrochemical Industry

The chemical and petrochemical industry deals with reactive substances that require careful isolation. Aluminum honeycomb blind plates provide an effective barrier, preventing the mixing of incompatible chemicals and reducing the risk of accidents. They also contribute to overall safety in chemical processes.

D. Electronics Manufacturing

Electronics manufacturing involves sensitive components that can be easily damaged by contamination or electrostatic discharge. Aluminum honeycomb blind plates help isolate production areas, protecting sensitive equipment and ensuring the quality of electronic products.

IV. Factors to Consider when Choosing Aluminum Honeycomb Blind Plates

When selecting aluminum honeycomb blind plates, several factors should be taken into consideration:

A. Material Selection

Choose plates made from high-quality aluminum to ensure durability and resistance to corrosion. The honeycomb core should be made from lightweight yet strong materials, such as aluminum alloy.

B. Plate Thickness and Strength

Consider the thickness and strength of the plates based on the specific requirements of the production environment. Thicker plates offer increased strength and rigidity, while thinner plates are suitable for less demanding applications.

C. Customization Options

Look for manufacturers that offer customization options to meet specific needs. This includes the ability to choose different sizes, shapes, and finishes to fit the production area seamlessly.

V. Installation and Maintenance of Aluminum Honeycomb Blind Plates

Proper installation and maintenance are crucial for maximizing the benefits of aluminum honeycomb blind plates. Follow manufacturer guidelines for installation techniques, ensuring a secure and tight fit. Regular cleaning and maintenance will help prolong the lifespan of the plates and ensure their continued effectiveness.

Conclusion

Aluminum honeycomb blind plates offer significant advantages in production isolation across various industries. Their ability to ensure complete medium separation, enhance safety, improve efficiency, and control noise and vibration makes them a valuable asset in industrial settings. By understanding the applications and factors to consider when choosing these plates, businesses can make informed decisions to optimize their production processes. With proper installation and maintenance, aluminum honeycomb blind plates can provide long-lasting benefits, contributing to a safer and more efficient working environment.

Aluminum Honeycomb Blind Plate: A Lightweight Solution for Strong and Durable Structures