The Impact of Maximizing Efficiency in 3D Printing Workflows

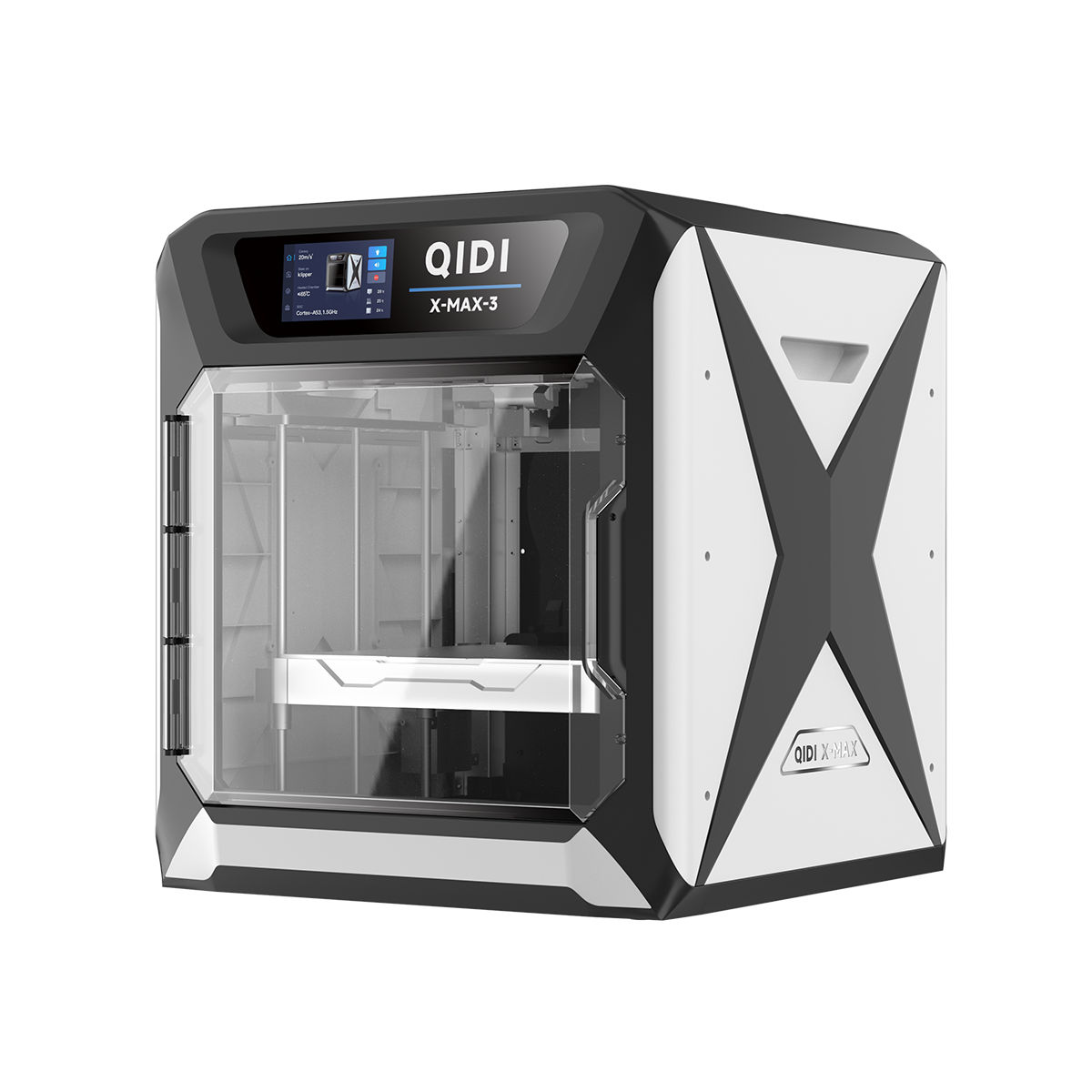

From this article you can learn efficient 3d printing workflows with x-max by qidi.Maximizing efficiency in 3D printing workflows is crucial for businesses looking to streamline their production processes. By optimizing the use of resources, reducing waste, and improving turnaround times, companies can significantly enhance their overall productivity and competitiveness in the market. The integration of advanced technologies such as X-Max by Qidi has revolutionized the way industries approach 3D printing, offering a range of benefits that contribute to maximizing efficiency.

Enhancing Productivity with X-Max by Qidi

One of the key advantages of leveraging X-Max by Qidi in 3D printing workflows is the ability to enhance productivity. The advanced features and capabilities of this technology enable businesses to produce high-quality prototypes and end-use parts with greater speed and accuracy. By optimizing the printing process and minimizing the need for manual intervention, X-Max by Qidi significantly reduces the time required to bring a concept from design to a physical object, thereby maximizing efficiency in the production cycle.

Optimizing Resource Utilization for Cost-Efficiency

Efficient 3D printing workflows with X-Max by Qidi also focus on optimizing resource utilization to achieve cost-efficiency. Through the implementation of smart printing strategies and material management techniques, businesses can minimize material wastage and reduce operational costs. This not only contributes to environmental sustainability but also enhances the overall profitability of the production process. By leveraging the capabilities of X-Max by Qidi, companies can achieve a balance between resource utilization and cost-effectiveness, thereby maximizing efficiency in their 3D printing operations.

Streamlining Workflow Processes for Seamless Integration

Another critical aspect of maximizing efficiency in 3D printing workflows with X-Max by Qidi is the seamless integration of the technology into existing workflow processes. By customizing the printing parameters, optimizing file preparation, and automating post-processing tasks, businesses can streamline their workflow processes to achieve greater efficiency and consistency in output quality. This level of integration not only reduces the likelihood of errors and rework but also ensures that the entire production cycle operates at its optimal capacity, ultimately maximizing efficiency in the industry.

In conclusion, the adoption of X-Max by Qidi in 3D printing workflows has redefined the standards for maximizing efficiency in the industry. By enhancing productivity, optimizing resource utilization, and streamlining workflow processes, businesses can achieve significant improvements in their overall operational efficiency and output quality. As the technology continues to evolve, it is essential for industries to embrace the full potential of X-Max by Qidi to stay ahead in the competitive landscape.