This article provides information about different kinds of software that are currently available and can be used without cost.

The Open Porous Media (OPM) flow simulator is an open-source piece of software that can be used to simulate, upscale, and visualize processes that occur in porous subsurface reservoirs. OPM is capable of formulating a wide variety of models, including the polymer module, the solvent module, and the foam model, all of which are used to simulate surfactant-injection processes.

BOOST Three-Pack

In the field of petroleum reservoir engineering, the BOAST 3-PC is a black-oil applied simulation tool (BOAST) that is routinely utilized for the performance of evaluation and design work. BOAST II, which was first introduced to the public in 1987, was developed with the intention of offering greater flexibility and overcoming some of the constraints that were present in the original BOAST. The model's versatility was significantly increased thanks to the addition of a large number of features. Drilling and Well Control Animation is predicated on the idea that reservoir fluids can be characterized by three fluid phases (oil, gas, and water) of constant composition, with physical properties that only vary with changes in pressure. BOOST 3 is capable of handling a variety of common issues that arise during field production, including but not limited to the following:

Studies on primary depletion and assessments of waterflooding operations are both included.

• A tracking method using bubblepoints.

• A method of automatic control that uses time steps.

• Plotting simulated data, which enables a comparison of the outcomes of as many as five separate simulation runs

• History matching by making use of oil, water, or gas production data, the gas/oil ratio or the water/oil ratio; the average reservoir pressure or bottomhole well pressure can also be matched.

The DuMux

Tracer tests to characterize both single- and dual-porosity oil reservoirs Single well, partitioning interwell, and single well wettability tracer tests Polymerflooding Surfactant flooding High-pH alkaline flooding Microbial enhanced oil recovery (EOR) Surfactant/foam and alkaline surfactant polymer (ASP)/foam EOR Tracer tests to characterize both

Controlling the profiles of oil wells using polymer gels

Developing a model of the formation damage caused by oil wells

Drilling in OpenLab. com.

OpenLab Drilling is a simulation software that combines a web-based online drilling simulator, drilling control room, and a functional full-scale on-site drilling rig

It was developed by the drilling and well modeling group at Norwegian NORCE in collaboration with University of Stavanger

The software is used for virtual drilling and well operations

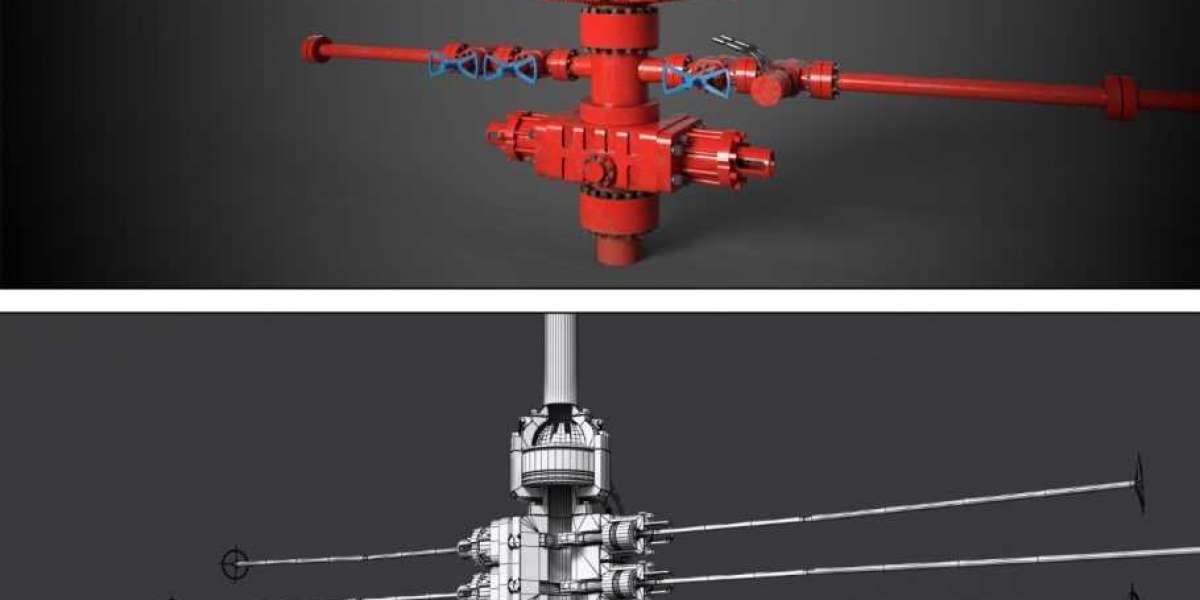

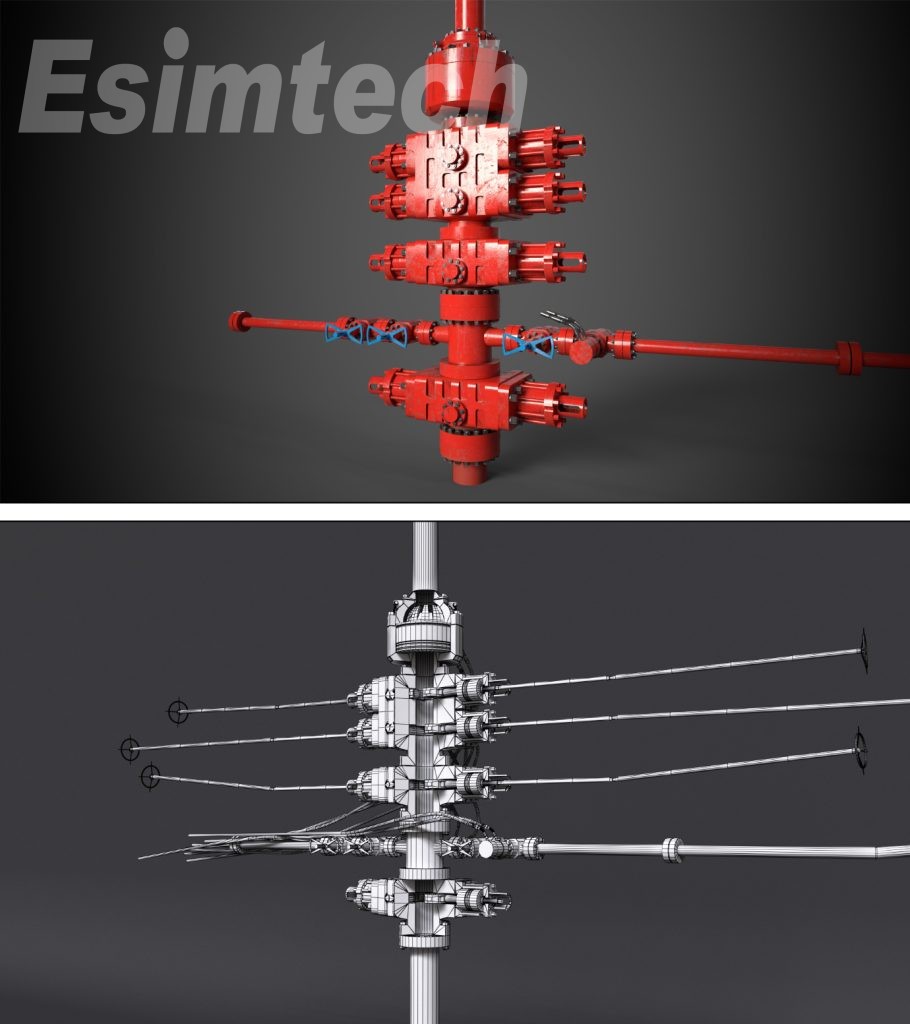

Simulator of the Well Control

LearnToDrill, in collaboration with Chevron (where they globally launched the drilling simulator), Lone Star College, and BP, developed the Well Control Simulator. It is one of the most cost-effective simulators available in the industry and complies with IADC WellSharp well control guidelines. It offers unrestricted practice time on the simulator with an intelligent assistant. To begin, you have the option of beginning with a setup that consists of 10 preset templates and configurations. Second, you have the ability to create wells that are unique to your needs (with parameters such as piping sizes, kick timing, etc.). The expected output is then finally presented in detailed graphs that illustrate the behavior of the pressure at various stages of the kill operation. These graphs can be saved as exportable PDF files after they have completed their presentation.